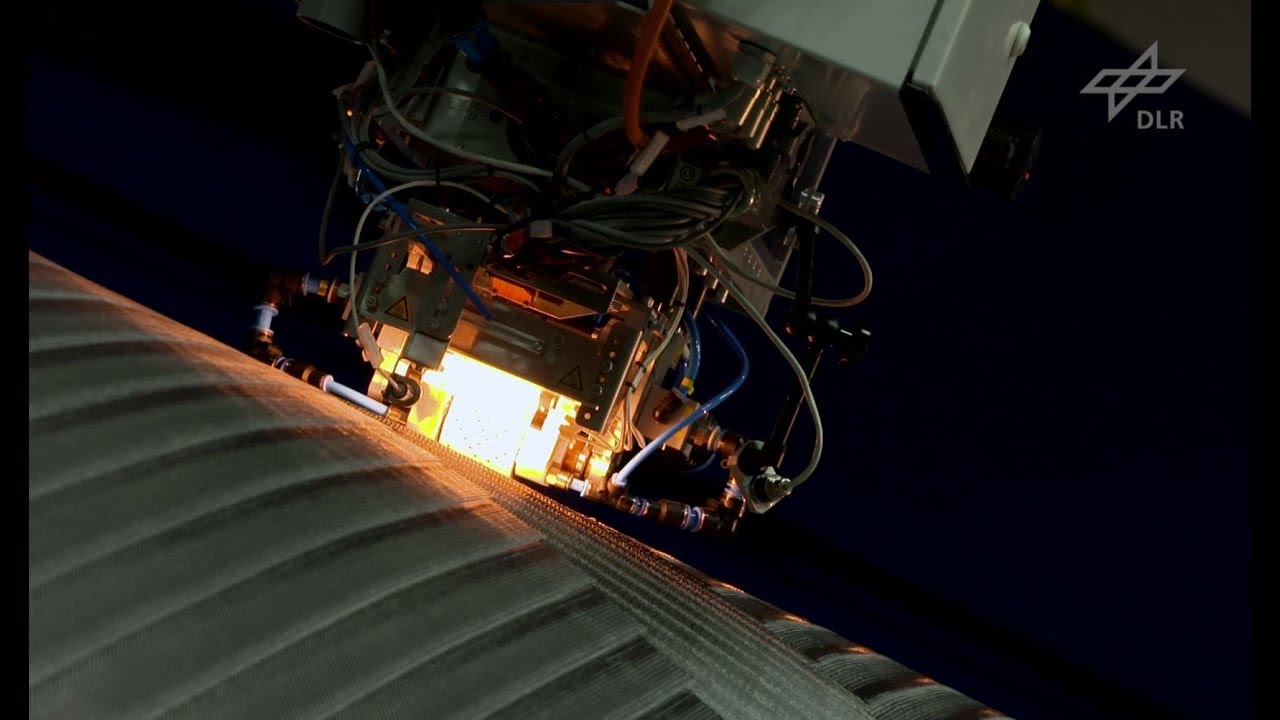

The Center for Lightweight Production Technology in Augsburg developed a new manufacturing process for future European launcher systems. We were looking for a process to produce a booster case in a very efficient way. A combination of fiber winding and dry fiber placement achieves a highly automated CFRP preforming. Subsequently the dry carbon fibers are impregnated with plastic material in a vacuum assisted infusion process. Finally the part is cured in an oven process.

The Center for Lightweight Production Technology in Augsburg developed a new manufacturing process for future European launcher systems. We were looking for a process to produce a booster case in a very efficient way. A combination of fiber winding and dry fiber placement achieves a highly automated CFRP preforming. Subsequently the dry carbon fibers are impregnated with plastic material in a vacuum assisted infusion process. Finally the part is cured in an oven process. After the process development a manufacturing demonstrator of the booster was built in a slightly modified way. It was successfully pressurized and destructive tested in 2017.

Contact: Lars Brandt, Lars.brandt@dlr.de

Details:

0 Comments